-

제품 정보

제품 상세설명

Overview

Rapid Thermal Processing (RTP) refer to a semiconductor manufacturing process which

instantly heats silicon wafer to high temperatures (up to 1100℃ / 2012℉) under

different atmospheric conditions such as oxygen or nitrogen.

The Korea Vacuum Tech, Ltd. RTP System offers the highest Rapid Thermal Annealing

(RTA) performance for a wide range of application with a low cost of ownership.

Designed to meet the most stringent requirements of today’s semiconductor

technologies and beyond, the RTP Module provides complete temperature control

necessary for advanced semiconductor manufacturing applications.

The Korea Vacuum Tech, Ltd. RTP system utilizes and array of unique technical feature

which provide optimal uniformity, repeatability and precision previously unachievable in

semiconductor manufacturing.

Features

≻ High-power Quartz Lamps

Wafers are heated by an array of high-power quartz lamps.

≻ Rapid Heating

The maximum heating rate of the wafer is 100℃/ sec (212℉/sec).

≻ Digital display shows both the actual wafer temperature as well as the desired pre-set temperature

PID constants can be easily set by the standard equipment auto-tuning function.

≻ Variable Pressure Range

Pressure ranges from high vacuum to ambient atmospheres with oxygen or nitrogen can be utilized.

≻ Compatible with various gases (Ar, H2, O2, N2)

Applications

≻ Silicide to Si process

≻ Annealing after ion implantation: sheet resistance

≻ LED process such as GaN

Overview

Rapid Thermal Processing (RTP) refer to a semiconductor manufacturing process which

instantly heats silicon wafer to high temperatures (up to 1100℃ / 2012℉) under

different atmospheric conditions such as oxygen or nitrogen.

The Korea Vacuum Tech, Ltd. RTP System offers the highest Rapid Thermal Annealing

(RTA) performance for a wide range of application with a low cost of ownership.

Designed to meet the most stringent requirements of today’s semiconductor

technologies and beyond, the RTP Module provides complete temperature control

necessary for advanced semiconductor manufacturing applications.

The Korea Vacuum Tech, Ltd. RTP system utilizes and array of unique technical feature

which provide optimal uniformity, repeatability and precision previously unachievable in

semiconductor manufacturing.

Features

≻ High-power Quartz Lamps

Wafers are heated by an array of high-power quartz lamps.

≻ Rapid Heating

The maximum heating rate of the wafer is 100℃/ sec (212℉/sec).

≻ Digital display shows both the actual wafer temperature as well as the desired pre-set temperature

PID constants can be easily set by the standard equipment auto-tuning function.

≻ Variable Pressure Range

Pressure ranges from high vacuum to ambient atmospheres with oxygen or nitrogen can be utilized.

≻ Compatible with various gases (Ar, H2, O2, N2)

Applications

≻ Silicide to Si process

≻ Annealing after ion implantation: sheet resistance

≻ LED process such as GaN

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATION

Substrate size

2” wafer

Substrate holder

2.5” SiC

Heating elements

Quartz Lamp

Chamber Material

Water or air cooled Al or SUS304 chamber

with quartz window

Pumping system:

Rotary pump

Gas control:

Mass Flow Meter or MFC

Specifications

ITEM

SPECIFICATION

Substrate size

2” wafer

Substrate holder

2.5” SiC

Heating elements

Quartz Lamp

Chamber Material

Water or air cooled Al or SUS304 chamber

with quartz window

Pumping system:

Rotary pump

Gas control:

Mass Flow Meter or MFC

-

Options

-

Control

제품 Control

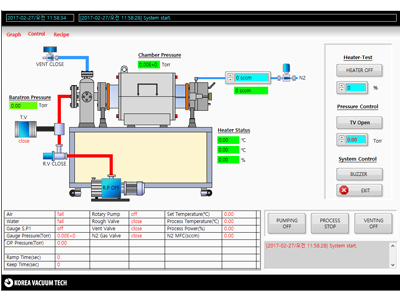

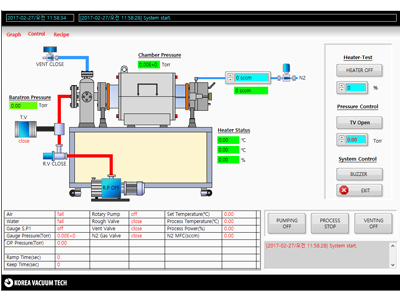

System Control

Pumping

This picture is a pumping screen. There are buttons on the screen to operate the pump and valve to keep the chamber under vacuum. In addition, MFC and throttle valves are controlled to create a process environment within the chamber.

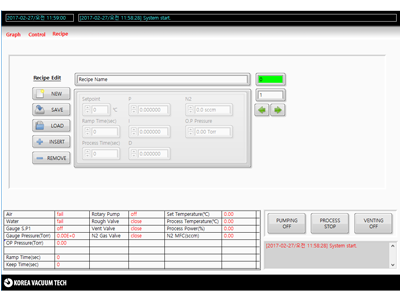

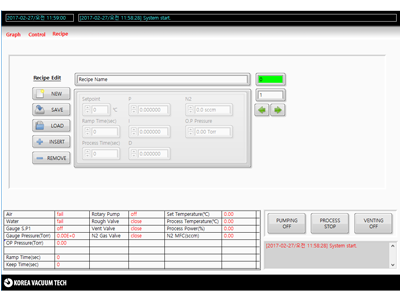

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

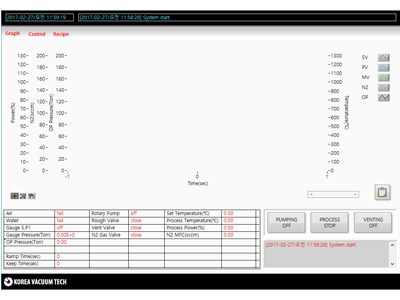

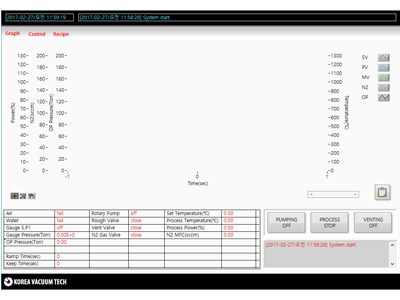

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount, Temperature and so on. You can record that data and make it into a file and compare it with the previous data.

System Control

Pumping

This picture is a pumping screen. There are buttons on the screen to operate the pump and valve to keep the chamber under vacuum. In addition, MFC and throttle valves are controlled to create a process environment within the chamber.

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount, Temperature and so on. You can record that data and make it into a file and compare it with the previous data.

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVR-2000 Series+0원