Josephson Junction System

-

A Josephson junction is a key component designed to allow electrons to travel through quantum tunneling through a thin insulating layer connecting two superconductors. Although this structure is miniscule in size that it is invisible to the naked eye, it plays a crucial role in implementing qubits, the fundamental unit of quantum computers, by precisely controlling current and phase. This technology is now a key factor of the development of superconducting quantum computers.

-

Aluminum is considered the most suitable material for fabricating Josephson junctions. The naturally formed thin, uniform oxide film (Al₂O₃) provides a stable insulating layer, enabling precise control of current and phase. Furthermore, its simple and highly reproducible process facilitates large-scale quantum chip fabrication, and its low noise makes it ideal for securing long qubit (coherence time) performance. These properties have made aluminum a key material for today's superconducting quantum computers.

-

Neobium (Nb) sputtering is an essential process for fabricating Josephson junctions. Nebium possesses a higher critical temperature and more stable superconducting properties than aluminum, enabling the fabrication of more reliable quantum devices. The uniform, dense films formed through the sputtering process are optimized for large-scale integrated circuit fabrication and are positioned as a key foundational technology driving the development of superconducting quantum computers.

-

Ion beam etching is a microfabrication process essential for fabricating Josephson junctions. Josephson junctions, which involve nanometer-thick insulating and superconducting layers, require extreme precision. Ion beam etching selectively removes only unnecessary components, creating a clean and uniform junction surface and optimizing intermetal contact characteristics to ensure stable supercurrent flow. This precision processing technology is a key enabler for high-performance qubit implementation and large-scale quantum chip fabrication.

-

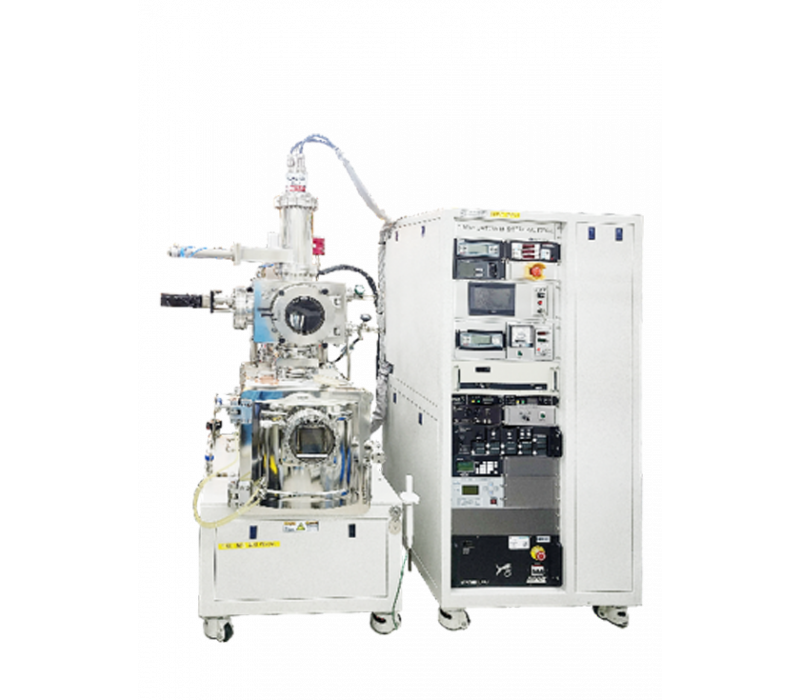

Josephson junction fabrication requires extreme precision, and ion beam etching and sputtering are key processes for achieving this. Ion beam etching selectively removes unnecessary film to ensure a clean and uniform bonding surface, while sputtering deposits a precise and uniform film of superconducting metals such as neodymium (Nb) or aluminum (Al). Our integrated vacuum system is designed to perform these two processes continuously within a single chamber. Contamination is minimized by eliminating sample exposure to the atmosphere between processes. This system simultaneously meets the stability, precision, and efficiency demands of researchers and industrial sites, providing the optimal solution for the development of next-generation superconducting quantum computers.