-

제품 정보

제품 상세설명

Overview

Korea Vacuum Tech, Ltd. (KVT) is proud to introduce the latest revolutionary addition to

our product line, the Intelsi-M Multi-Function PVD system. Despite its compact

convenient size, easy operation and affordability, functionality is in no way sacrificed.

The Intelsi-M is capable of thin film deposition utilizing Sputter, E-Beam and Thermal

Source technologies and can accommodate variable material types in sample sizes up to

4" (101.2mm). The modular design of the Intelsi-M makes it highly configurable to meet

specific customer needs and numerous stock options are also available. A fully

automated Laptop PC helps round out this extremely usable yet robust diminutive

package.

Advantages

≻ Easy to install, easy to operate

≻ Precise reproducible coatings - consistent

≻ Fully adaptable to a wide range of specimens

≻ Compact design / small footprint

≻ Quick and simple loading / unloading

Features

≻ Extreme versatility

≻ High capacity vacuum pumping

≻ Fully automated PC control

≻ Capable of producing very thin resultant films

Overview

Korea Vacuum Tech, Ltd. (KVT) is proud to introduce the latest revolutionary addition to

our product line, the Intelsi-M Multi-Function PVD system. Despite its compact

convenient size, easy operation and affordability, functionality is in no way sacrificed.

The Intelsi-M is capable of thin film deposition utilizing Sputter, E-Beam and Thermal

Source technologies and can accommodate variable material types in sample sizes up to

4" (101.2mm). The modular design of the Intelsi-M makes it highly configurable to meet

specific customer needs and numerous stock options are also available. A fully

automated Laptop PC helps round out this extremely usable yet robust diminutive

package.

Advantages

≻ Easy to install, easy to operate

≻ Precise reproducible coatings - consistent

≻ Fully adaptable to a wide range of specimens

≻ Compact design / small footprint

≻ Quick and simple loading / unloading

Features

≻ Extreme versatility

≻ High capacity vacuum pumping

≻ Fully automated PC control

≻ Capable of producing very thin resultant films

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Turbo molecular pump

Loadlock Chamber

Stainless steel

Substrate Heating Unit

SiC / 4”

Sample Loading/Unloading Unit

Manual

Pressure Control Unit

Auto

Vacuum Gauge Controller

ATM ~ 1.0E-10Torr

Gas Supply Unit

MFC (Ar, O2, etc..)

Power Supply Unit

DC / AC

Deposition Source

Sputtering Cathode 1EA, Thermal Source 2EA

Target & Boat

3" Target, 1/2” (w) x 2 (L) x 0.2 (T) Boat

Film Thickness Uniformity

Less than ±5%

Ultimate Pressure

Less than 5.0E-7Torr

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Turbo molecular pump

Loadlock Chamber

Stainless steel

Substrate Heating Unit

SiC / 4”

Sample Loading/Unloading Unit

Manual

Pressure Control Unit

Auto

Vacuum Gauge Controller

ATM ~ 1.0E-10Torr

Gas Supply Unit

MFC (Ar, O2, etc..)

Power Supply Unit

DC / AC

Deposition Source

Sputtering Cathode 1EA, Thermal Source 2EA

Target & Boat

3" Target, 1/2” (w) x 2 (L) x 0.2 (T) Boat

Film Thickness Uniformity

Less than ±5%

Ultimate Pressure

Less than 5.0E-7Torr

-

Options

제품 Options

Options

ITEM

SPECIFICATIONS

Description

Intelsi-LL

Intelsi-LS1

Intelsi-LS2

Intelsi-LE

Chamber

SUS304, Circle type, Top door open

Dimensions

M: 830(W) x 892(D) x 1150(H)

E-Beam Source

Single pocket – 1.5cc

N/A

N/A

4cc-6pockets/7cc-

4pockets

E-Beam Power Supply

3kW E-Beam power

supply

N/A

N/A

6kW E-Beam power

supply

Gas Supply

Ar MFC control (Optional O2 MFC, N2 MFC)

N/A

Pressure Control

Manual throttle valve (Optional Auto Throttle Valve)

N/A

Process

Ultimate pressure : less than 5 x 10E-6 torr

Deposition Uniformity

less than ±5% @ 2 inch

less than ±5% @ 3 inch

less than ±5% @ 3 inch

Sputtering Source

Target size : 1 inch

Target: 1 inch – 3ea

Target size : 3inch – 3ea

N/A

Sputtering Power Supply

1kW RF Power Supply

1kW DC Power Supply

N/A

Substrate

Size : up to 4” piece

up to 4” piece

up to 4” piece

Rotation Speed

Rotation : 0 – 30 RPM

Heater

Heating : up to 800°C by SiC heating element

System Control

PLC based PC control

System Software

Software : Labview

Thermal Source

W boat or

basket type

N/A

N/A

N/A

Thermal Power Supply

3kW DC power supply

N/A

N/A

N/A

Utilities

Electric Power : 220V, 3P, 30A

PCW : 1 ~ 2 kgf/cm2, 10 L/M

CDA : 6 ~ 7 kgf/cm2

Vacuum Gauge

PLC interface communication

Vacuum Pumping

Turbo Molecular Pump + Rotary pump

Weight

~ 300 kg (~660 pound )

Options

ITEM

SPECIFICATIONS

Description

Intelsi-LL

Intelsi-LS1

Intelsi-LS2

Intelsi-LE

Chamber

SUS304, Circle type, Top door open

Dimensions

M: 830(W) x 892(D) x 1150(H)

E-Beam Source

Single pocket – 1.5cc

N/A

N/A

4cc-6pockets/7cc-

4pockets

E-Beam Power Supply

3kW E-Beam power

supply

N/A

N/A

6kW E-Beam power

supply

Gas Supply

Ar MFC control (Optional O2 MFC, N2 MFC)

N/A

Pressure Control

Manual throttle valve (Optional Auto Throttle Valve)

N/A

Process

Ultimate pressure : less than 5 x 10E-6 torr

Deposition Uniformity

less than ±5% @ 2 inch

less than ±5% @ 3 inch

less than ±5% @ 3 inch

Sputtering Source

Target size : 1 inch

Target: 1 inch – 3ea

Target size : 3inch – 3ea

N/A

Sputtering Power Supply

1kW RF Power Supply

1kW DC Power Supply

N/A

Substrate

Size : up to 4” piece

up to 4” piece

up to 4” piece

Rotation Speed

Rotation : 0 – 30 RPM

Heater

Heating : up to 800°C by SiC heating element

System Control

PLC based PC control

System Software

Software : Labview

Thermal Source

W boat or

basket type

N/A

N/A

N/A

Thermal Power Supply

3kW DC power supply

N/A

N/A

N/A

Utilities

Electric Power : 220V, 3P, 30A

PCW : 1 ~ 2 kgf/cm2, 10 L/M

CDA : 6 ~ 7 kgf/cm2

Vacuum Gauge

PLC interface communication

Vacuum Pumping

Turbo Molecular Pump + Rotary pump

Weight

~ 300 kg (~660 pound )

-

Control

제품 Control

System Control

Vacuum

This figure shows the pumping screen. This screen consists of each valve, pump action button, and automatic button. The biggest difference from Semi-Auto is the automatic button, so if you proceed with these buttons in sequence, one sample will be completed.

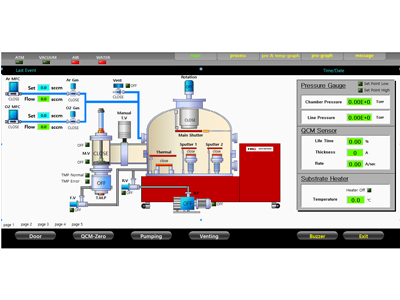

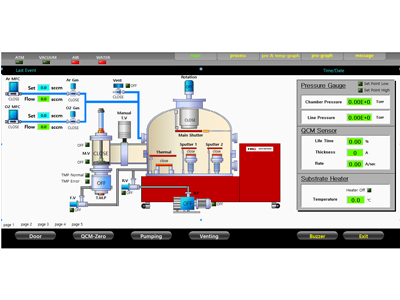

Process

The figure shows the process screen. This screen shows the buttons that control the gas flow rate, valve, power etc. required for the process.

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount and so on. You can record that data, make it into a file, and compare it with the previous data.

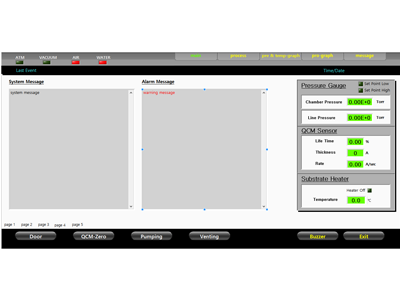

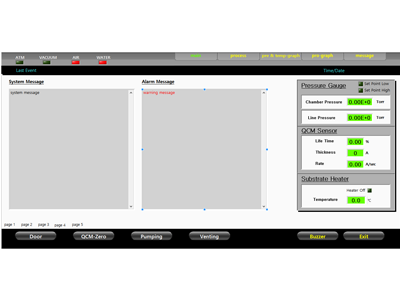

Message

The figure is a graph screen. The picture consists of status message and notification messages.

System Control

Vacuum

This figure shows the pumping screen. This screen consists of each valve, pump action button, and automatic button. The biggest difference from Semi-Auto is the automatic button, so if you proceed with these buttons in sequence, one sample will be completed.

Process

The figure shows the process screen. This screen shows the buttons that control the gas flow rate, valve, power etc. required for the process.

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount and so on. You can record that data, make it into a file, and compare it with the previous data.

Message

The figure is a graph screen. The picture consists of status message and notification messages.

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

Intelsi-L Series+0원