-

제품 정보

제품 상세설명

Overview

Korea Vacuum Tech, Ltd. (KVT) is proud to introduce the latest revolutionary addition to

our product line, the ALD system.

ALD has the such advantages over other conventional deposition methods as excellent

uniform thickness, low processing temperature, and precise film thickness control.

ICP plasma enhanced atomic layer deposition has many advantages, such

as the wide process window, high film density, low impurity contents, and broad choice

of precursor chemistry and/or reactants compared to the conventional ALD and metal

organic atomic layer deposition (MOALD)Methods. KVA-4000 series is designed and

developed to unique hot wall, top flow, dual-chamber and also, KVAC-4000,

KVA-ICP4000 series, KVA-CCP4000 series has the deposition of highest quality film with

excellent uniformity.

Overview

Korea Vacuum Tech, Ltd. (KVT) is proud to introduce the latest revolutionary addition to

our product line, the ALD system.

ALD has the such advantages over other conventional deposition methods as excellent

uniform thickness, low processing temperature, and precise film thickness control.

ICP plasma enhanced atomic layer deposition has many advantages, such

as the wide process window, high film density, low impurity contents, and broad choice

of precursor chemistry and/or reactants compared to the conventional ALD and metal

organic atomic layer deposition (MOALD)Methods. KVA-4000 series is designed and

developed to unique hot wall, top flow, dual-chamber and also, KVAC-4000,

KVA-ICP4000 series, KVA-CCP4000 series has the deposition of highest quality film with

excellent uniformity.

-

Specifications

제품 Specifications

Specifications (CCP type)

ITEM

SPECIFICATIONS

Chamber

Process & Loadlock Chamber

Substrate size

Piece to 6 inches

Substrate Heating

Temperature range: up to 752°F (400°F)

Temperature Uniformity: ±41°F (±5°C)

Base Pressure & Operation Pressure

Less than 1.0E-3 Torr: Rotary or Dry pump

Less than 1.0E-6 Torr: Turbo Molecular Pump (Option)

Process < 10 Torr: Rotary or Dry pump

Plasma Source

CCP Type: RF Power: 300W

Gas Nozzle

2 channel

Precursors

Up to 2, Temperature: 250°C (Jacket)

Mass flow controller

Precusor: Ar(Bubbling) / Purge: Ar or N2

Reactant(Plasma): O2, NH3, H2, etc..

Auto Pressure Controller

Throttle valve & Baratron Sensor

Specifications (CCP type)

ITEM

SPECIFICATIONS

Chamber

Process & Loadlock Chamber

Substrate size

Piece to 6 inches

Substrate Heating

Temperature range: up to 752°F (400°F)

Temperature Uniformity: ±41°F (±5°C)

Base Pressure & Operation Pressure

Less than 1.0E-3 Torr: Rotary or Dry pump

Less than 1.0E-6 Torr: Turbo Molecular Pump (Option)

Process < 10 Torr: Rotary or Dry pump

Plasma Source

CCP Type: RF Power: 300W

Gas Nozzle

2 channel

Precursors

Up to 2, Temperature: 250°C (Jacket)

Mass flow controller

Precusor: Ar(Bubbling) / Purge: Ar or N2

Reactant(Plasma): O2, NH3, H2, etc..

Auto Pressure Controller

Throttle valve & Baratron Sensor

-

Options

-

Control

제품 Control

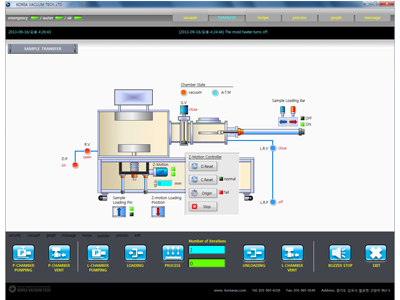

System Control

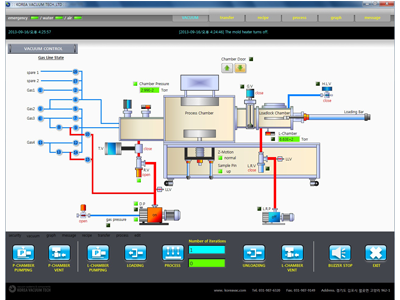

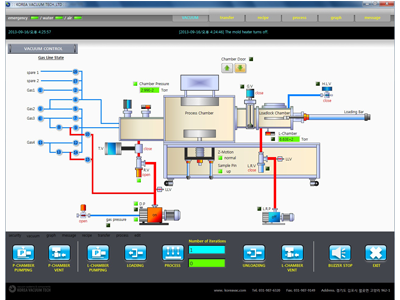

Vacuum

This screen shows the vacuum screen. This screen

consists of each valve, pump action button, automatic

button. The automatic function provides convenience

to the user. if you proceed with these buttons in

sequence, one sample will be completed.

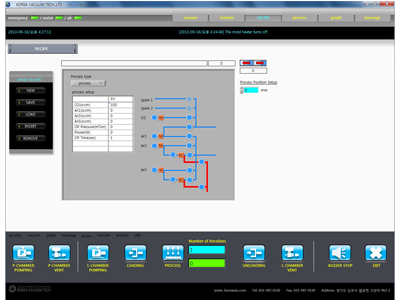

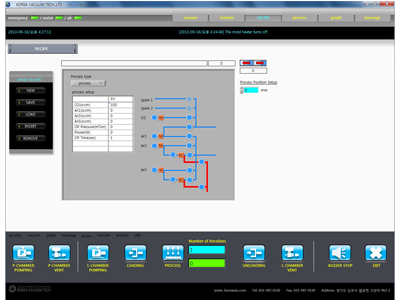

Recipe

The figure shows the recipe screen. This screen

contains boxes for entering the process conditions

required for deposition. Input all the boxes and press

the Process button to automatically deposit according to the

input process conditions.

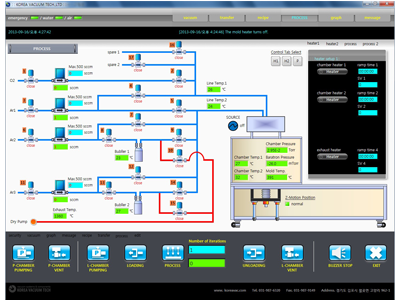

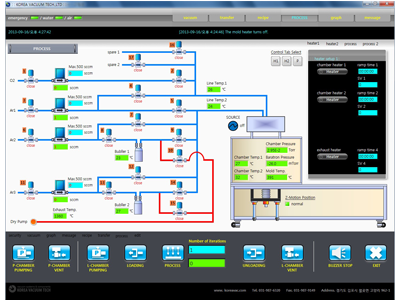

Process

The figure shows the process screen. This screen shows

the buttons that can control the gas flow rate, valve,

power etc. required for the process.

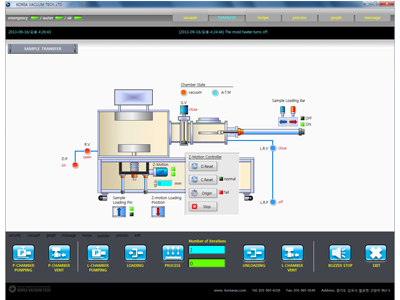

Transfer

The figure shows the Transfer screen. In this screen, there

are buttons that allow you to manipulate the part you will use

to move samples from the load lock chamber to the

process chamber , such as the loading arm, z-motion.

Graph

The figure shows the graph screen. This screen shows

vacuum degree, power amount, deposition rate, thickness

and so on. You can record that data and make it into a

file and compare it with the previous data.

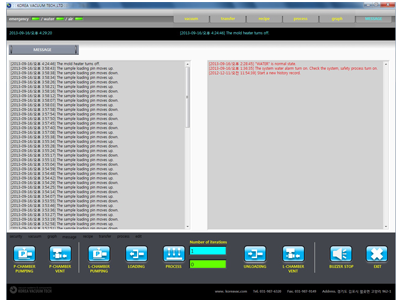

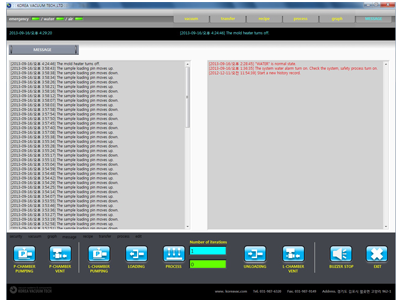

Message

The picture is a graph screen. The picture consists of status

message notification messages

System Control

Vacuum

This screen shows the vacuum screen. This screen

consists of each valve, pump action button, automatic

button. The automatic function provides convenience

to the user. if you proceed with these buttons in

sequence, one sample will be completed.

Recipe

The figure shows the recipe screen. This screen

contains boxes for entering the process conditions

required for deposition. Input all the boxes and press

the Process button to automatically deposit according to the

input process conditions.

Process

The figure shows the process screen. This screen shows

the buttons that can control the gas flow rate, valve,

power etc. required for the process.

Transfer

The figure shows the Transfer screen. In this screen, there

are buttons that allow you to manipulate the part you will use

to move samples from the load lock chamber to the

process chamber , such as the loading arm, z-motion.

Graph

The figure shows the graph screen. This screen shows

vacuum degree, power amount, deposition rate, thickness

and so on. You can record that data and make it into a

file and compare it with the previous data.

Message

The picture is a graph screen. The picture consists of status

message notification messages

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVA-CCP4000L+0원