-

제품 정보

제품 상세설명

Overview

Korea Vacuum Tech, Ltd. proudly introduces the latest

addition to our family of products, the Intelsi-R Series ‘Bench Top’ RTP

system, which puts the annealing process into a compact size.

Designed to process samples up to 2” (50.8mm) wafer size in various

gas environments using precise digital display readout and full

computer control, the Intelsi-R Series can be conveniently configured,

is simple to operate and easy to maintain.The modular design of the Intelsi-M

makes it highly configurable to meet specific customer needs and numerous

stock options are also available. A fully automated Laptop PC helps round out

this extremely usable yet robust diminutive package.

Advantages

≻ Easy to install, easy to operate

≻ Precise reproducible coatings - consistent

≻ Compact design / small footprint

≻ Quick and simple loading / unloading

Features

≻ Rapid Heating: 100℃/sec (212℉/sec)

≻ Extreme versatility

≻ High capacity vacuum pumping

≻ Fully automated PC control

≻ Capable of producing very thin resultant films

Applications

≻ Annealing after ion implantation

≻ III -V semiconductor

≻ Damage recovery after dry etch

≻ Silicide processing

Overview

Korea Vacuum Tech, Ltd. proudly introduces the latest

addition to our family of products, the Intelsi-R Series ‘Bench Top’ RTP

system, which puts the annealing process into a compact size.

Designed to process samples up to 2” (50.8mm) wafer size in various

gas environments using precise digital display readout and full

computer control, the Intelsi-R Series can be conveniently configured,

is simple to operate and easy to maintain.The modular design of the Intelsi-M

makes it highly configurable to meet specific customer needs and numerous

stock options are also available. A fully automated Laptop PC helps round out

this extremely usable yet robust diminutive package.

Advantages

≻ Easy to install, easy to operate

≻ Precise reproducible coatings - consistent

≻ Compact design / small footprint

≻ Quick and simple loading / unloading

Features

≻ Rapid Heating: 100℃/sec (212℉/sec)

≻ Extreme versatility

≻ High capacity vacuum pumping

≻ Fully automated PC control

≻ Capable of producing very thin resultant films

Applications

≻ Annealing after ion implantation

≻ III -V semiconductor

≻ Damage recovery after dry etch

≻ Silicide processing

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Rotary Pump

Temperature Range

100℃ ~ 1000℃ (212℉ ~ 1832℉)

Temperature uniformity

Less than <± 5℃ (41℉) for 50.8mm (2”) wafer

Heating element

Quartz Lamp

Ultimate Pressure

Less than 5.0E-3Torr

Dimensions

626mm(W) x 520mm(D) x 475mm(H)

- 24.5”(W) x 20.5” (D) x 18.75” (H)

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Rotary Pump

Temperature Range

100℃ ~ 1000℃ (212℉ ~ 1832℉)

Temperature uniformity

Less than <± 5℃ (41℉) for 50.8mm (2”) wafer

Heating element

Quartz Lamp

Ultimate Pressure

Less than 5.0E-3Torr

Dimensions

626mm(W) x 520mm(D) x 475mm(H)

- 24.5”(W) x 20.5” (D) x 18.75” (H)

-

Options

-

Control

제품 Control

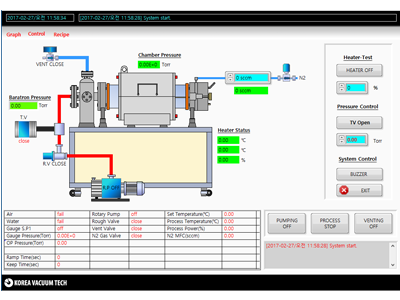

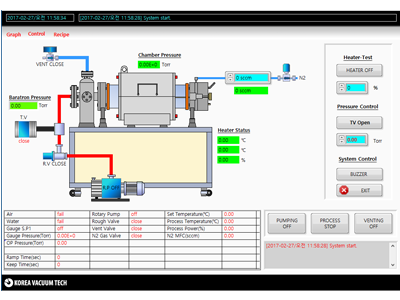

System Control

Pumping

This picture is a pumping screen. There are buttons on the screen to operate the pump and valve to keep the chamber under vacuum. In addition, MFC and throttle valves are controlled to create a process environment within the chamber.

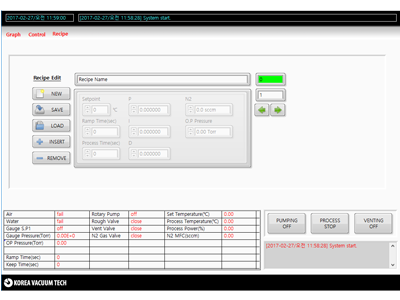

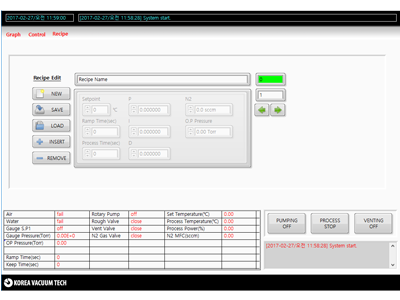

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

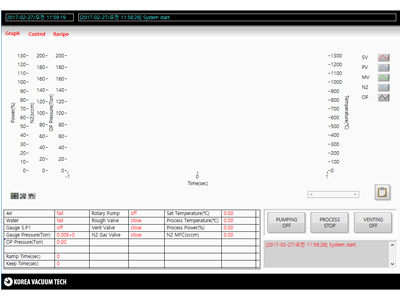

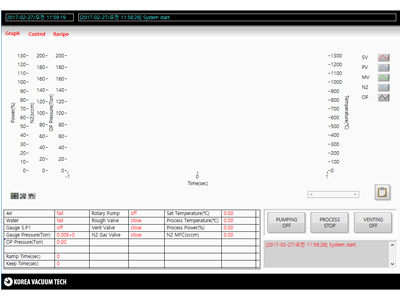

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount, Temperature and so on. You can record that data and make it into a file and compare it with the previous data.

System Control

Pumping

This picture is a pumping screen. There are buttons on the screen to operate the pump and valve to keep the chamber under vacuum. In addition, MFC and throttle valves are controlled to create a process environment within the chamber.

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount, Temperature and so on. You can record that data and make it into a file and compare it with the previous data.

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

Bench Top RTP+0원