-

제품 정보

제품 상세설명

Overview

KVT has developed the evaporator system with high precision deposition rate control

and unique design & technology. KVE series is designed and manufactured to

deposition equipment with variable item. KVE-TG Series is consisted of deposition

system with glove box system. These systems can prevent the oxidation of sample from external air.

If you use the mask when you deposit the thin film, you can make the device without venting the chamber.

Also if you enter the deposition condition to recipe, you will always get the thin film of same characteristic.

Features

≻ Mixing source

The system has multi thermal source. It can use the organic source with the metal source. Also can be possible that is co-deposition.

≻ Multi-Layer Deposition

Multiple source assemblies provide for sequential multi-layer or complex alloy deposition In Situ.

≻ Make the complete sample at once.

The system has the mask changer. So you can get the complete sample without venting the chamber. It has advantage that reduce the chamber pumping time and prevent the oxidation of sample.

Overview

KVT has developed the evaporator system with high precision deposition rate control

and unique design & technology. KVE series is designed and manufactured to

deposition equipment with variable item. KVE-TG Series is consisted of deposition

system with glove box system. These systems can prevent the oxidation of sample from external air.

If you use the mask when you deposit the thin film, you can make the device without venting the chamber.

Also if you enter the deposition condition to recipe, you will always get the thin film of same characteristic.

Features

≻ Mixing source

The system has multi thermal source. It can use the organic source with the metal source. Also can be possible that is co-deposition.

≻ Multi-Layer Deposition

Multiple source assemblies provide for sequential multi-layer or complex alloy deposition In Situ.

≻ Make the complete sample at once.

The system has the mask changer. So you can get the complete sample without venting the chamber. It has advantage that reduce the chamber pumping time and prevent the oxidation of sample.

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

TMP / Cryo pump

Loadlock Chamber

Glove box intergrated

Substrate Unit

Rotation / Heating / Cooling

Sample Size

4” or more

Power Supply Unit

10V,300A / 10V,100A

Source Type & Number

Boat, Crucible / Two or more

Process Control Type

Auto

Film Thickness Uniformity

< ±5%

Ultimate Pressure

< 5.0E-7Torr

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

TMP / Cryo pump

Loadlock Chamber

Glove box intergrated

Substrate Unit

Rotation / Heating / Cooling

Sample Size

4” or more

Power Supply Unit

10V,300A / 10V,100A

Source Type & Number

Boat, Crucible / Two or more

Process Control Type

Auto

Film Thickness Uniformity

< ±5%

Ultimate Pressure

< 5.0E-7Torr

-

Options

-

Control

제품 Control

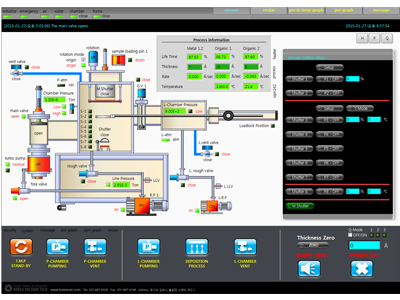

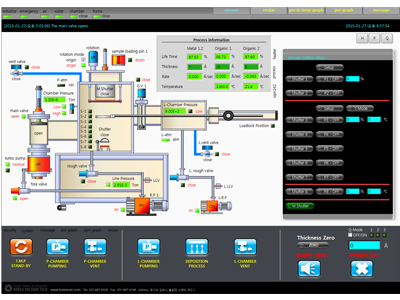

System Control

Vacuum

This screen shows the pumping screen. This screen consists of each valve, pump action button, automatic button. The biggest difference from Semi Auto is the automatic button, so if you proceed with these buttons in sequence, one sample will be completed.

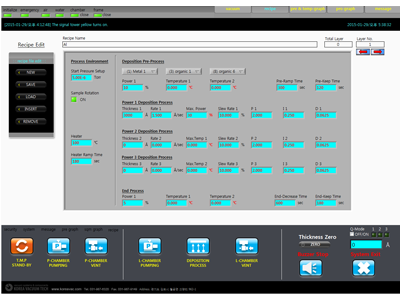

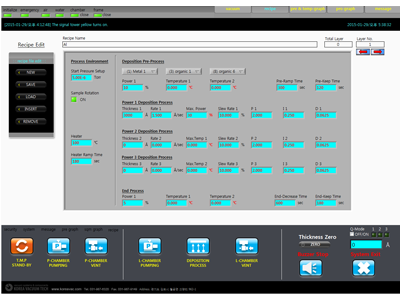

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

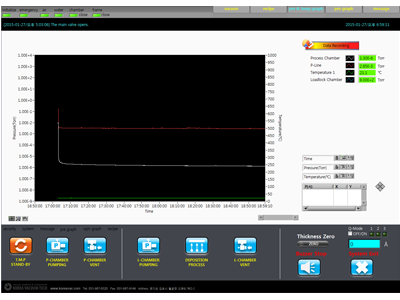

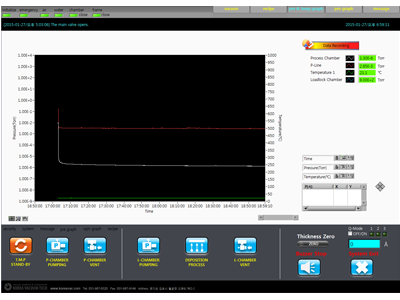

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount thickness, deposition rate and so on. You can record that data and make it into a file and compare it with the previous data.

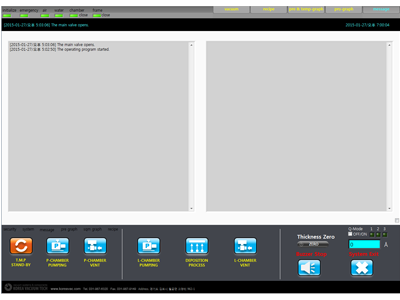

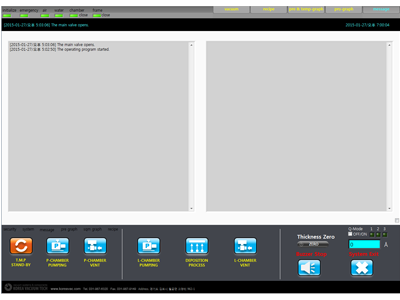

Message

The picture is a graph screen. The picture consists of status message notification messages

System Control

Vacuum

This screen shows the pumping screen. This screen consists of each valve, pump action button, automatic button. The biggest difference from Semi Auto is the automatic button, so if you proceed with these buttons in sequence, one sample will be completed.

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount thickness, deposition rate and so on. You can record that data and make it into a file and compare it with the previous data.

Message

The picture is a graph screen. The picture consists of status message notification messages

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVE-TG4000L+0원