-

제품 정보

제품 상세설명

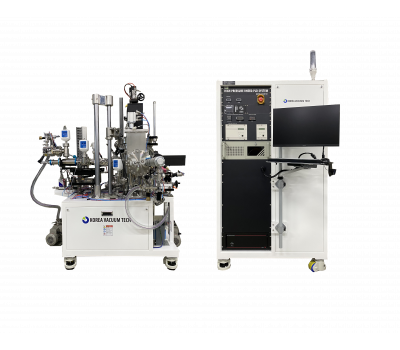

Overview

PLD (Pulsed Laser Deposition) is a physical deposition method that utilizes a high energy

focused laser. Conceptually and experimentally. PLD is extremely simple. It consists of a

target holder and a substrate holder housed in a vacuum chamber. A set of optical

components focus and raster a high-power laser (the external source) into a

concentrated beam over the target surface which vaporizes target materials to

ultimately deposite thin film.

Advantages

≻ Allows for the use of various targets and for the in-situ deposition of multi-layers

≻ Consists of simple hardware

≻ Simple system maintenance

≻ Various aspect of beam-target-substrate positioning

≻ Temperature uniformity of substrate

≻ Pyrometer Port

≻ Laser strength measurement port

≻ Ellipsometry port

Overview

PLD (Pulsed Laser Deposition) is a physical deposition method that utilizes a high energy

focused laser. Conceptually and experimentally. PLD is extremely simple. It consists of a

target holder and a substrate holder housed in a vacuum chamber. A set of optical

components focus and raster a high-power laser (the external source) into a

concentrated beam over the target surface which vaporizes target materials to

ultimately deposite thin film.

Advantages

≻ Allows for the use of various targets and for the in-situ deposition of multi-layers

≻ Consists of simple hardware

≻ Simple system maintenance

≻ Various aspect of beam-target-substrate positioning

≻ Temperature uniformity of substrate

≻ Pyrometer Port

≻ Laser strength measurement port

≻ Ellipsometry port

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

UHV chamber Ultimate Pressure

up to 5.0E-9Torr

Two Chamber System

Process chamber & Loadlock chamber

Uniformity Zone of Substrate Heating

Ø15 mm

Substrate Temperature

850°C ± 5°C in oxygen

Operating Pressure

0.01mTor ~ 10 Torr

Target Carousel

one inch (25.4mm) diameter for four targets

Normal Angle of Incidence

Laser beam on target : 45° with respect to target normal

Loading type

Easy to load or unload sample and target by magnetic transfer

Option1

RHEED (Reflection High-Energy Electron Diffraction)

Option2

CCD Camera for Oscillation of RHEED

Option3

Pyrometer for measuring substrate temperature

Specifications

ITEM

SPECIFICATIONS

UHV chamber Ultimate Pressure

up to 5.0E-9Torr

Two Chamber System

Process chamber & Loadlock chamber

Uniformity Zone of Substrate Heating

Ø15 mm

Substrate Temperature

850°C ± 5°C in oxygen

Operating Pressure

0.01mTor ~ 10 Torr

Target Carousel

one inch (25.4mm) diameter for four targets

Normal Angle of Incidence

Laser beam on target : 45° with respect to target normal

Loading type

Easy to load or unload sample and target by magnetic transfer

Option1

RHEED (Reflection High-Energy Electron Diffraction)

Option2

CCD Camera for Oscillation of RHEED

Option3

Pyrometer for measuring substrate temperature

-

Options

-

Control

제품 Control

System Control

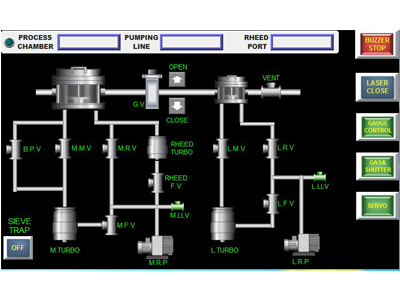

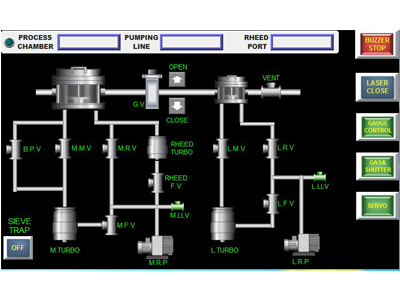

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and valve are easily operated with one touch

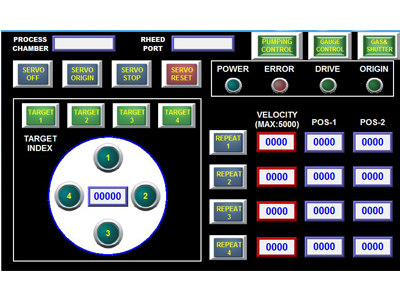

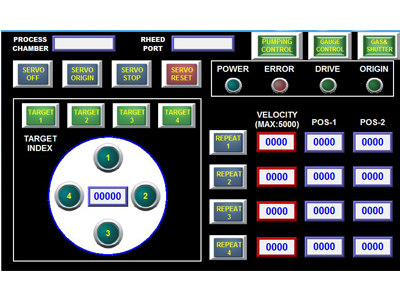

Servo

The picture shows the servo screen. When you press the target button on this screen, target is rotated and you can see the target you selected. It also includes a target trigger function.

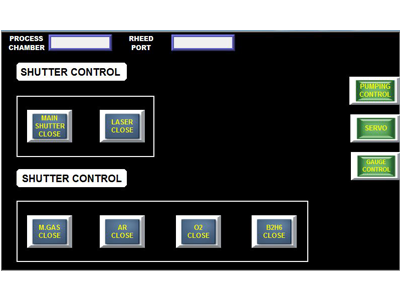

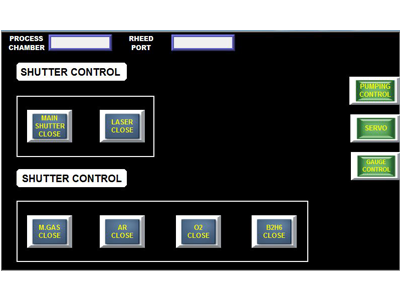

Shutter

This screen shows the shutter screen. There are buttons on the screen to operate the substrate shutter, the gas valve, and the sputter gun shutter.

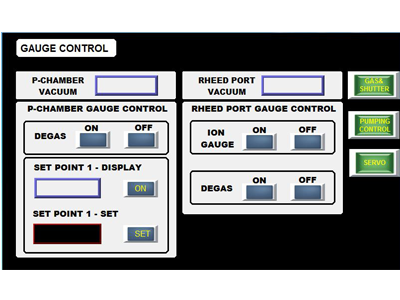

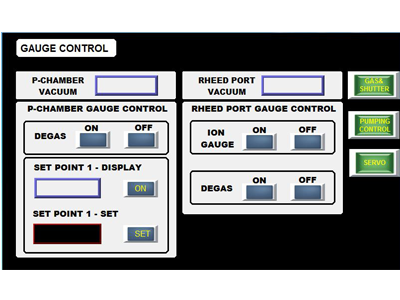

Gauge Control

This screen shows the gauge control screen. There are buttons

on the screen

System Control

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and valve are easily operated with one touch

Servo

The picture shows the servo screen. When you press the target button on this screen, target is rotated and you can see the target you selected. It also includes a target trigger function.

Shutter

This screen shows the shutter screen. There are buttons on the screen to operate the substrate shutter, the gas valve, and the sputter gun shutter.

Gauge Control

This screen shows the gauge control screen. There are buttons

on the screen -

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVP-2000 Series+0원