-

제품 정보

제품 상세설명

Overview

Korea Vacuum Tech, Ltd. (KVT) is proud to introduce the latest revolutionary addition

to our product line, the CVD system. Chemical Vapor Deposition is a chemical reactive

process used to produce high-purity, high-performance solid materials in a vacuum state.

In a typical CVD process, the wafer (substrate) is exposed to one or more volatile precursors

which react and / or decompose on the substrate surface to produce a desired deposit.

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a unique form of the CVD

process used primarily to deposit thin films from a gaseous state (vapor) to a solid state

on some substrate. PECVD is not dependent upon thermal energy alone to create of

maintain a chemical reaction but rather it uses RF-enhanced glow discharge to convey

energy to a reactive gas which subsequently, in a vacuum environment, sets the

conditions necessary for effective thin film deposition.

Features

≻ Compared to other CVD application, PECVD allows for operations in

a high-vacuum, low-temp environment

≻ Specially designed gas shower head provides uniform gas flow – consistent

film thickness over a surface

≻ Can distribute multiple gases, independently about the substrate and mixed

outside of gas shower head

≻ Semi – or Fully- Automate processing available

≻ Capable of multi-layer, co-deposition processing

≻ High deposition rates-fast!

Overview

Korea Vacuum Tech, Ltd. (KVT) is proud to introduce the latest revolutionary addition

to our product line, the CVD system. Chemical Vapor Deposition is a chemical reactive

process used to produce high-purity, high-performance solid materials in a vacuum state.

In a typical CVD process, the wafer (substrate) is exposed to one or more volatile precursors

which react and / or decompose on the substrate surface to produce a desired deposit.

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a unique form of the CVD

process used primarily to deposit thin films from a gaseous state (vapor) to a solid state

on some substrate. PECVD is not dependent upon thermal energy alone to create of

maintain a chemical reaction but rather it uses RF-enhanced glow discharge to convey

energy to a reactive gas which subsequently, in a vacuum environment, sets the

conditions necessary for effective thin film deposition.

Features

≻ Compared to other CVD application, PECVD allows for operations in

a high-vacuum, low-temp environment

≻ Specially designed gas shower head provides uniform gas flow – consistent

film thickness over a surface

≻ Can distribute multiple gases, independently about the substrate and mixed

outside of gas shower head

≻ Semi – or Fully- Automate processing available

≻ Capable of multi-layer, co-deposition processing

≻ High deposition rates-fast!

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Material : SUS304 / Anodized Al6061

Loadlock Chamber

N/A

Vacuum Pumping Station

TMP & Dry Pump

Gas shower Head

Shower Head with insulator/RF bias electrode isolation

Pressure Control

Auto Throttle Valve & CDG Sensor

Substrate Heating Type

- Heating element size: 4” ~ 6”

- Heating element type: SiC, Molded

Gas Supply Unit

Mass Flow Controller & valve

Plasma Source

RF generator with matching network

Process control

KVC-P4000

KVC-P4000L

KVC-P2000

KVC-P2000L

PC Control

By Labview

PC Control

By Labview

Semi-Auto

Semi-Auto

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Material : SUS304 / Anodized Al6061

Loadlock Chamber

N/A

Vacuum Pumping Station

TMP & Dry Pump

Gas shower Head

Shower Head with insulator/RF bias electrode isolation

Pressure Control

Auto Throttle Valve & CDG Sensor

Substrate Heating Type

- Heating element size: 4” ~ 6”

- Heating element type: SiC, Molded

Gas Supply Unit

Mass Flow Controller & valve

Plasma Source

RF generator with matching network

Process control

KVC-P4000

KVC-P4000L

KVC-P2000

KVC-P2000L

PC Control

By Labview

PC Control

By Labview

Semi-Auto

Semi-Auto

-

Options

-

Control

제품 Control

System Control

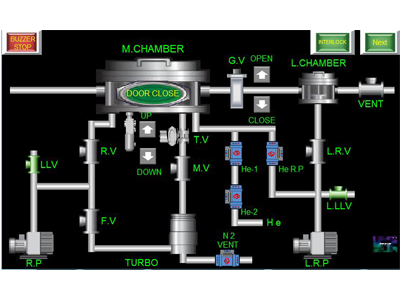

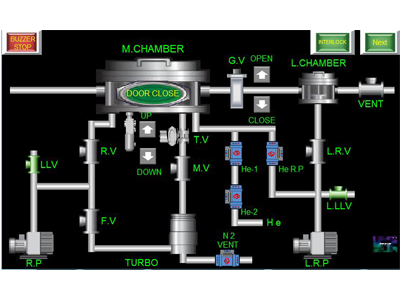

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and valve

are easily operated with one touch.

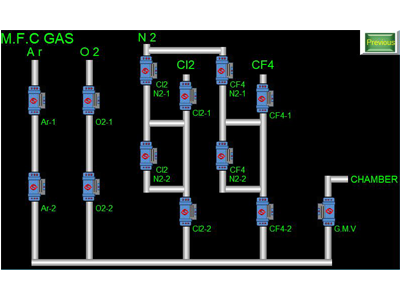

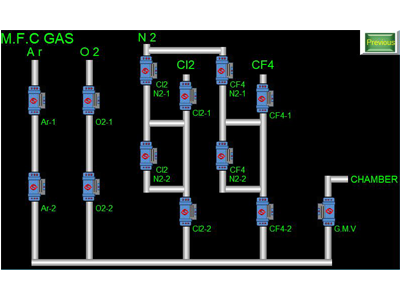

Gas Control

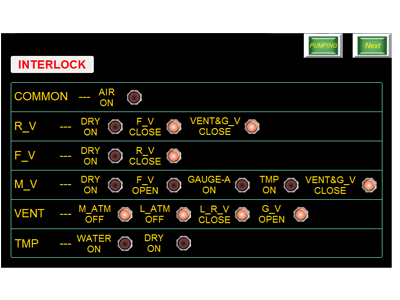

This picture shows the gas control screen.Interlock

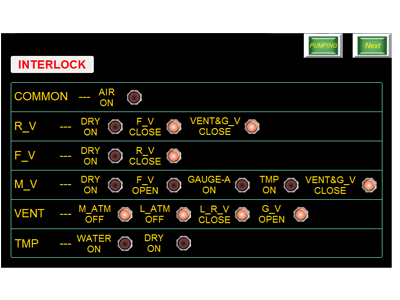

This picture shows the interlock screen. Basically, the interlock is set so that it does not work when you deviate from the correct method of use for your safety.

System Control

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and valve

are easily operated with one touch.

Gas Control

This picture shows the gas control screen.Interlock

This picture shows the interlock screen. Basically, the interlock is set so that it does not work when you deviate from the correct method of use for your safety.

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVC-P2000+0원