-

제품 정보

제품 상세설명

Overview

Korea Vacuum Tech, Inc. (KVT) is proud to introduce the latest revolutionary addition to our product line, the CVD system. Chemical Vapor Deposition is a chemical reactive process used to produce high –purity, high performance solid materials in a vacuum state. In a typical CVD process, the water(substrate) is exposed to one or more volatile precursors which react and / or decompose on the substrate surface to produce a desired deposit. Thermal Chemical Vapor Deposition(Thermal CVD) is a unique form of the CVD process used primarily to deposit thin lms from a gaseous state(Vapor) to a solid state on some substrate. Thermal CVD is dependent upon thermal energy to create of maintain a chemical reaction.

Features

≻ 3 Zone Furnace for temperature up to 1000℃

≻ Sample size : up to 2”

≻ Easy to sample loading & unloading by loading bar

≻ 3” dia. Quartz Tube

≻ Operation pressure ~ 1Torr

≻ No water cooling

Overview

Korea Vacuum Tech, Inc. (KVT) is proud to introduce the latest revolutionary addition to our product line, the CVD system. Chemical Vapor Deposition is a chemical reactive process used to produce high –purity, high performance solid materials in a vacuum state. In a typical CVD process, the water(substrate) is exposed to one or more volatile precursors which react and / or decompose on the substrate surface to produce a desired deposit. Thermal Chemical Vapor Deposition(Thermal CVD) is a unique form of the CVD process used primarily to deposit thin lms from a gaseous state(Vapor) to a solid state on some substrate. Thermal CVD is dependent upon thermal energy to create of maintain a chemical reaction.

Features

≻ 3 Zone Furnace for temperature up to 1000℃

≻ Sample size : up to 2”

≻ Easy to sample loading & unloading by loading bar

≻ 3” dia. Quartz Tube

≻ Operation pressure ~ 1Torr

≻ No water cooling

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Dimension

1990(W) x 850(D) x 1200 (H)

Weight

250 kg

Loading bar

Sample retract & extend

Substrate

Size : Piece to 2 inch

Temperature

Heating: up to 1000℃ on substrate

Three zone controlled furnace

Vacuum Pumping

Rotary pump

Vacuum Gauge

Convection gauge

Gas Supply

Ar, H2, CH4, N2 MFC

Pressure control

Auto throttle valve & CDG sensor

Specifications

ITEM

SPECIFICATIONS

Dimension

1990(W) x 850(D) x 1200 (H)

Weight

250 kg

Loading bar

Sample retract & extend

Substrate

Size : Piece to 2 inch

Temperature

Heating: up to 1000℃ on substrate

Three zone controlled furnace

Vacuum Pumping

Rotary pump

Vacuum Gauge

Convection gauge

Gas Supply

Ar, H2, CH4, N2 MFC

Pressure control

Auto throttle valve & CDG sensor

-

Options

-

Control

제품 Control

System Control

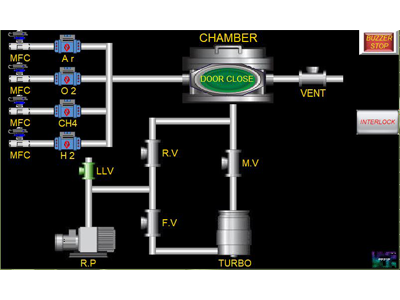

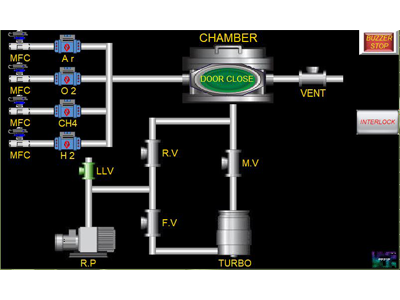

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and

valve are easily operated with one touch.

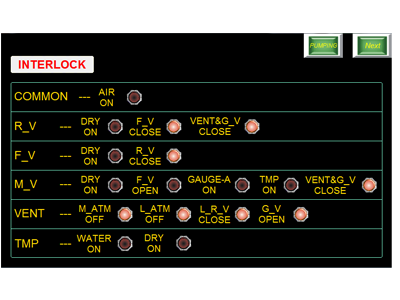

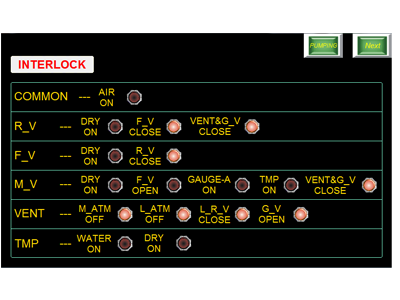

Interlock

This picture shows the interlock screen. Basically,

the interlock is set so that it does not work when you

deviate from the correct method of use for your safety.

System Control

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and

valve are easily operated with one touch.

Interlock

This picture shows the interlock screen. Basically,

the interlock is set so that it does not work when you

deviate from the correct method of use for your safety.

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVC-T2000L+0원