-

제품 정보

제품 상세설명

Overview

An evaporator uses an electric resistance heater or high-energy beam to melt material

and to raise its vapor pressure to a useful range. This process takes place in a high

vacuum state to allow the vapor to reach the substrate without reacting with or

scattering against other gas-phase atoms in the chamber while reducing the

incorporation of impurities from the residual gas in the vacuum chamber. The KVE Series

evaporation systems are capable of fabricating multi-layer thin films by applying this

co-deposition process.

Features

≻ Excellent Thickness Uniformity

The KVE Series E-Beam Evaporator System provide excellent thickness uniformity of

resultant films. if you deposit the thin film under same conditions, you will get a thin films

of same characteristics.

≻ Full Auto control

These systems provide the ‘auto button’ to user for convenience of user. Fully automated

vacuum process control system.

≻ Always maintain high vacuum degree in process

These systems have a process chamber and a loadlock chamber. Loadlock chamber is used

for sample loading. So process chamber is always maintained high vacuum state.

Overview

An evaporator uses an electric resistance heater or high-energy beam to melt material

and to raise its vapor pressure to a useful range. This process takes place in a high

vacuum state to allow the vapor to reach the substrate without reacting with or

scattering against other gas-phase atoms in the chamber while reducing the

incorporation of impurities from the residual gas in the vacuum chamber. The KVE Series

evaporation systems are capable of fabricating multi-layer thin films by applying this

co-deposition process.

Features

≻ Excellent Thickness Uniformity

The KVE Series E-Beam Evaporator System provide excellent thickness uniformity of

resultant films. if you deposit the thin film under same conditions, you will get a thin films

of same characteristics.

≻ Full Auto control

These systems provide the ‘auto button’ to user for convenience of user. Fully automated

vacuum process control system.

≻ Always maintain high vacuum degree in process

These systems have a process chamber and a loadlock chamber. Loadlock chamber is used

for sample loading. So process chamber is always maintained high vacuum state.

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Cryo / TMP

Loadlock Chamber

Top door, Stainless steel

Substrate Unit

Rotation / Heating / Cooling

Sample Size

4inch ~

Vacuum Gauge Controller

ATM ~ 1.0E-10Torr

Power Supply Unit

6kW, 8kW, 10kW

Crucible Size

4cc, 7cc, 15cc, 25cc

Pocket Number

Single, 4, 6

Film Thickness Uniformity

< ±5%

Ultimate Pressure

< 5.0E-7Torr

System Control

PLC based PC auto

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Cryo / TMP

Loadlock Chamber

Top door, Stainless steel

Substrate Unit

Rotation / Heating / Cooling

Sample Size

4inch ~

Vacuum Gauge Controller

ATM ~ 1.0E-10Torr

Power Supply Unit

6kW, 8kW, 10kW

Crucible Size

4cc, 7cc, 15cc, 25cc

Pocket Number

Single, 4, 6

Film Thickness Uniformity

< ±5%

Ultimate Pressure

< 5.0E-7Torr

System Control

PLC based PC auto

-

Options

-

Control

제품 Control

System Control

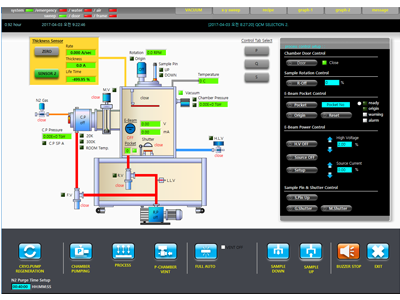

Pumping

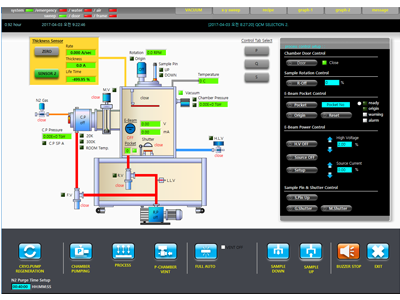

This screen shows the pumping screen. This screen consists of each valve, pump action button, automatic button, P, Q, S tap. The biggest difference from Semi Auto is the automatic button, so if you proceed with these buttons in sequence, one sample will be completed.

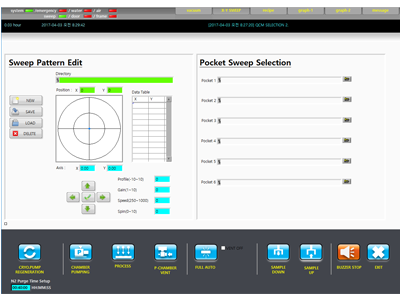

X-Y Sweeper

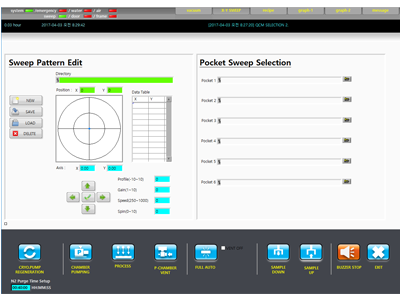

The picture shows the X-Y sweeper screen. This window can be saved pattern of e-beam to files. You can also load saved files. By entering various patterns for each pocket, you can get a stable deposition rate according to the characteristics of the source.

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

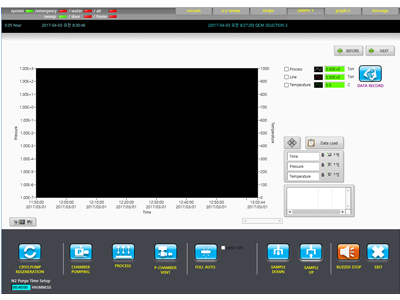

Graph

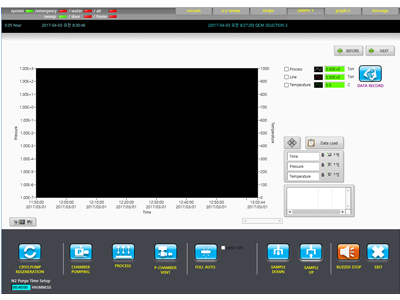

The figure shows the graph screen. This screen shows vacuum degree, power amount, deposition rate, thickness and so on. You can record that data and make it into a file and compare it with the previous data.

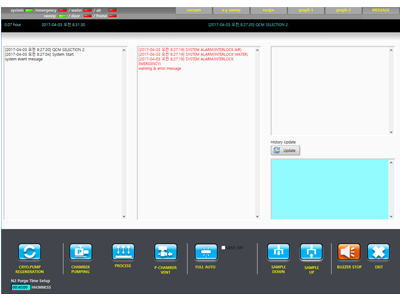

Message

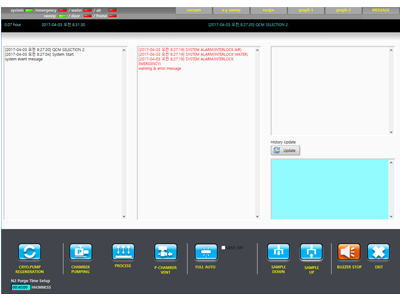

The picture is a graph screen. The picture consists of status message notification messages

System Control

Pumping

This screen shows the pumping screen. This screen consists of each valve, pump action button, automatic button, P, Q, S tap. The biggest difference from Semi Auto is the automatic button, so if you proceed with these buttons in sequence, one sample will be completed.

X-Y Sweeper

The picture shows the X-Y sweeper screen. This window can be saved pattern of e-beam to files. You can also load saved files. By entering various patterns for each pocket, you can get a stable deposition rate according to the characteristics of the source.

Recipe

The figure shows the recipe screen. This screen contains boxes for entering the process conditions required for deposition. Input all the boxes and press the Process button to automatically deposit according to the input process conditions.

Graph

The figure shows the graph screen. This screen shows vacuum degree, power amount, deposition rate, thickness and so on. You can record that data and make it into a file and compare it with the previous data.

Message

The picture is a graph screen. The picture consists of status message notification messages

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVE-E4000L Series+0원