-

제품 정보

제품 상세설명

Overview

Ion-Beam etching is a versatile process for pattern delineation and material modification.

The low pressure, line-of-sight nature of beam techniques provides a flexibility of

directional bombardment not available in other plasma processes. The ability to etch

virtually any material by the sputtering process opens a wide variety of diverse

applications.

Features

≻ High selectivity, uniform plasma

≻ Simple configuration makes maintenance easy

≻ The physical and chemical etching systems are controlled independently

≻ Low damage & contamination

≻ Physical etching using Ar Ion-Beam distributes reactive gases such as Cl2, He, BCl3 evenly around substrate.

Overview

Ion-Beam etching is a versatile process for pattern delineation and material modification.

The low pressure, line-of-sight nature of beam techniques provides a flexibility of

directional bombardment not available in other plasma processes. The ability to etch

virtually any material by the sputtering process opens a wide variety of diverse

applications.

Features

≻ High selectivity, uniform plasma

≻ Simple configuration makes maintenance easy

≻ The physical and chemical etching systems are controlled independently

≻ Low damage & contamination

≻ Physical etching using Ar Ion-Beam distributes reactive gases such as Cl2, He, BCl3 evenly around substrate.

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

System configuration

R&D

Substrate size

2” - 6” (50.8mm - 150mm)

Operation pressure (Torr)

> 1.0E-4 Torr

Uniformity within substrate /

substrate to substrate surfaces

± 5% max

Ion source

3cm ~ 20scm (@1” ~ 8”)

Substrate

Tilt / Rotation / Cooling

Ultimate Pressure

1.0E-6Torr

Specifications

ITEM

SPECIFICATIONS

System configuration

R&D

Substrate size

2” - 6” (50.8mm - 150mm)

Operation pressure (Torr)

> 1.0E-4 Torr

Uniformity within substrate /

substrate to substrate surfaces

± 5% max

Ion source

3cm ~ 20scm (@1” ~ 8”)

Substrate

Tilt / Rotation / Cooling

Ultimate Pressure

1.0E-6Torr

-

Options

-

Control

제품 Control

System Control

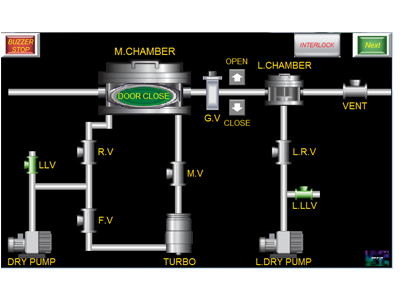

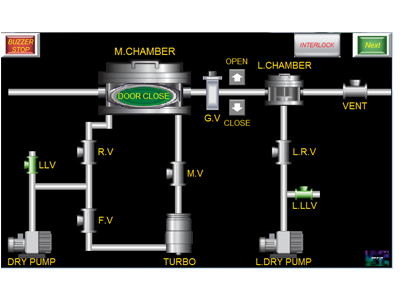

Pumping

The figure shows the pumping screen. Pumping screens

have valves and pumps. The pump and valve are easily

operated with one touch.

Process Control

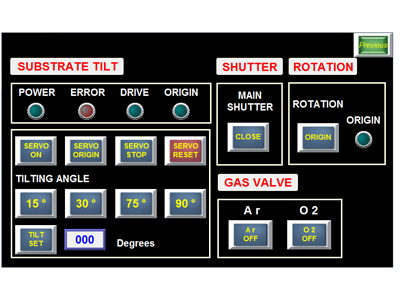

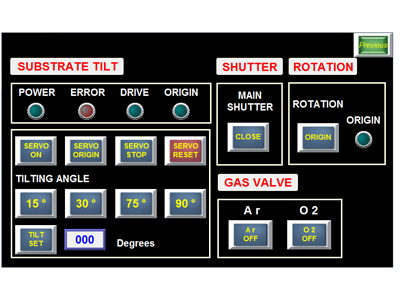

This picture shows the substrate tilt, shutter, rotation,

gas valve control screen.

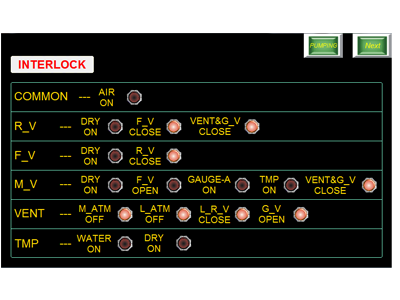

Interlock

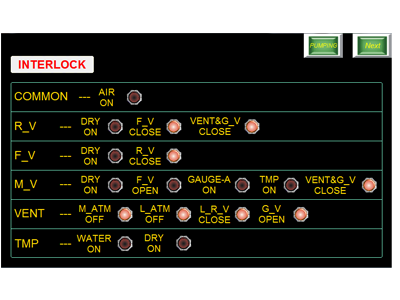

This picture shows the interlock screen. Basically, the

nterlock is set so that it does not work when you deviate

from the correct method of use for your safety.

System Control

Pumping

The figure shows the pumping screen. Pumping screens

have valves and pumps. The pump and valve are easily

operated with one touch.

Process Control

This picture shows the substrate tilt, shutter, rotation,

gas valve control screen.

Interlock

This picture shows the interlock screen. Basically, the

nterlock is set so that it does not work when you deviate

from the correct method of use for your safety.

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVET-B2000L+0원