-

제품 정보

제품 상세설명

Overview

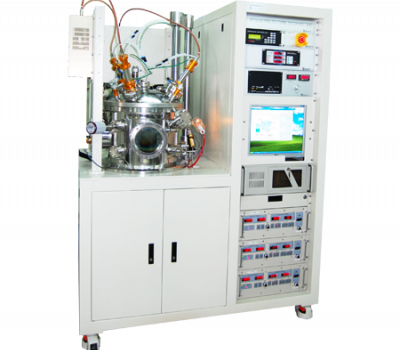

Sputter deposition is a technique used to deposit thin films of a material onto a surface

(substrate). Atoms and ions of a given material are made to collide. The resulting

momentum exchange disperses incident ions which further perpetuate activity setting

off collision cascades in the target. This activity drives the sputtering process. When

such cascades recoil and reach the target surface with an energy above the surface

binding energy, and atom can be ejected. If the target is thin on an atomic scale the

collision cascade can reach the back side of the target and atoms can escape the

surface binding energy in transmission. The average number of atoms ejected from the

target per incident ion is called the “sputter yield” and depends on the ion incident

angle, the energy of the ion, the masses of the ion and target atoms, and the surface

binding energy of atoms in the target.

Features

≻ Excellent Thickness Uniformity

The KVS Series RF&DC Sputtering System provide excellent thickness uniformity of resultant films even for substrates

that have the same diameter as the sputtering cathode assembly

≻ No loadlock chamber

≻ Semi-auto system control by PLC

Overview

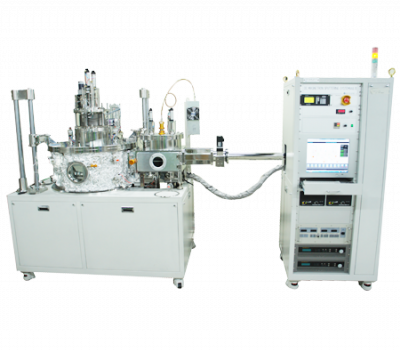

Sputter deposition is a technique used to deposit thin films of a material onto a surface

(substrate). Atoms and ions of a given material are made to collide. The resulting

momentum exchange disperses incident ions which further perpetuate activity setting

off collision cascades in the target. This activity drives the sputtering process. When

such cascades recoil and reach the target surface with an energy above the surface

binding energy, and atom can be ejected. If the target is thin on an atomic scale the

collision cascade can reach the back side of the target and atoms can escape the

surface binding energy in transmission. The average number of atoms ejected from the

target per incident ion is called the “sputter yield” and depends on the ion incident

angle, the energy of the ion, the masses of the ion and target atoms, and the surface

binding energy of atoms in the target.

Features

≻ Excellent Thickness Uniformity

The KVS Series RF&DC Sputtering System provide excellent thickness uniformity of resultant films even for substrates

that have the same diameter as the sputtering cathode assembly

≻ No loadlock chamber

≻ Semi-auto system control by PLC

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Turbo molecular pump

Loadlock Chamber

N/A

Substrate Heating Unit

SiC / 2”, 3”, 4”, 6”, 8”

Sample Loading/Unloading Unit

N/A

Pressure Control Unit

Auto / Semi-auto / Manual

Vacuum Gauge Controller

ATM ~ 1.0E-10Torr

Gas Supply Unit

MFC (Ar, O2, N2, H2, etc..)

Power Supply Unit

RF / DC / Pulsed DC

Target Size

2”, 3”, 4”, 6”

Film Thickness Uniformity

Less than ±5%

Ultimate Pressure

Less than 5.0E-7Torr

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Turbo molecular pump

Loadlock Chamber

N/A

Substrate Heating Unit

SiC / 2”, 3”, 4”, 6”, 8”

Sample Loading/Unloading Unit

N/A

Pressure Control Unit

Auto / Semi-auto / Manual

Vacuum Gauge Controller

ATM ~ 1.0E-10Torr

Gas Supply Unit

MFC (Ar, O2, N2, H2, etc..)

Power Supply Unit

RF / DC / Pulsed DC

Target Size

2”, 3”, 4”, 6”

Film Thickness Uniformity

Less than ±5%

Ultimate Pressure

Less than 5.0E-7Torr

-

Options

-

Control

제품 Control

System Control

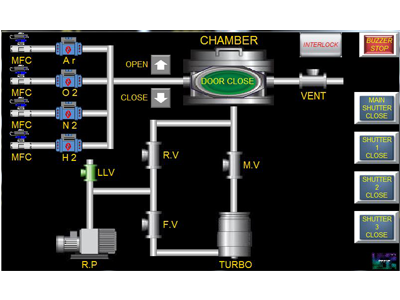

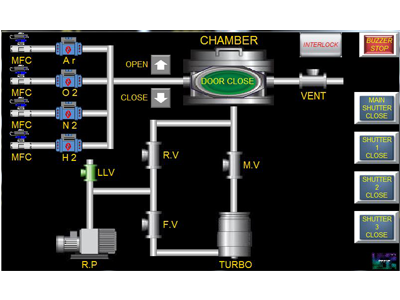

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and valve

are easily operated with one touch.

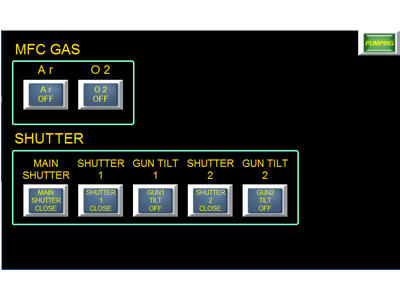

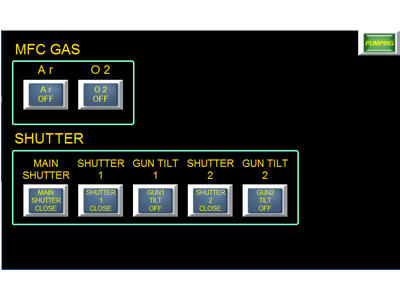

Shutter

This screen shows the shutter screen. There are buttons on

the screen to operate the substrate shutter, the gas valve,

and the sputter gun shutter.

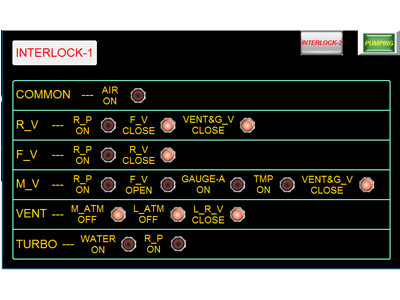

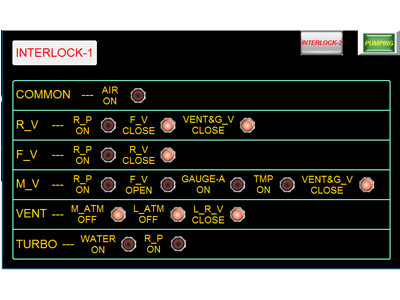

Interlock

This picture shows the interlock screen. Basically, the

interlock is set so that it does not work when you

deviate from the correct method of use for your safety.

System Control

Pumping

The figure shows the pumping screen. Pumping

screens have valves and pumps. The pump and valve

are easily operated with one touch.

Shutter

This screen shows the shutter screen. There are buttons on

the screen to operate the substrate shutter, the gas valve,

and the sputter gun shutter.

Interlock

This picture shows the interlock screen. Basically, the

interlock is set so that it does not work when you

deviate from the correct method of use for your safety.

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVS-2000+0원