-

제품 정보

제품 상세설명

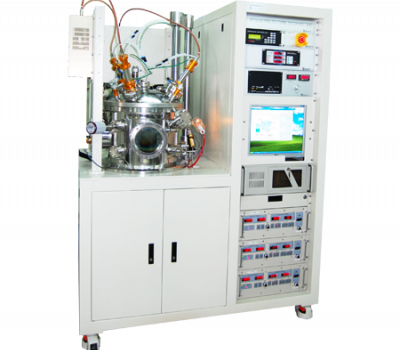

Overview

Sputter deposition is a technique used to deposit thin films of a material onto a surface

(substrate). Atoms and ions of a given material are made to collide. The resulting

momentum exchange disperses incident ions which further perpetuate activity setting

off collision cascades in the target. This activity drives the sputtering process. When

such cascades recoil and reach the target surface with an energy above the surface

binding energy, and atom can be ejected. If the target is thin on an atomic scale the

collision cascade can reach the back side of the target and atoms can escape the

surface binding energy in transmission. The average number of atoms ejected from the

target per incident ion is called the “sputter yield” and depends on the ion incident

angle, the energy of the ion, the masses of the ion and target atoms, and the surface

binding energy of atoms in the target.

Features

≻ Ion Beam Sputtering

Permits independent control over the energy and the current density of the bombarding ions.

≻ Ion Beam Sources

Permits Sputtered coatings to be deposited at very low inert working-gas pressure (<10-4Torr)

onto substrates not in contact with a plasma.

≻ Good Film Thickness Uniformity

Even with targets of same diameter as substrate.

≻ Low Pressure Process

Maintains discharge at a pressure range of about 10-4Torr (roughly one order of magnitude

lower than the conventional sputter discharge pressure.)

Overview

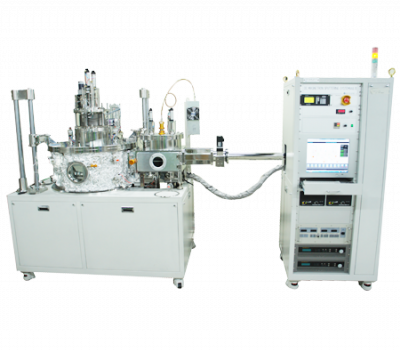

Sputter deposition is a technique used to deposit thin films of a material onto a surface

(substrate). Atoms and ions of a given material are made to collide. The resulting

momentum exchange disperses incident ions which further perpetuate activity setting

off collision cascades in the target. This activity drives the sputtering process. When

such cascades recoil and reach the target surface with an energy above the surface

binding energy, and atom can be ejected. If the target is thin on an atomic scale the

collision cascade can reach the back side of the target and atoms can escape the

surface binding energy in transmission. The average number of atoms ejected from the

target per incident ion is called the “sputter yield” and depends on the ion incident

angle, the energy of the ion, the masses of the ion and target atoms, and the surface

binding energy of atoms in the target.

Features

≻ Ion Beam Sputtering

Permits independent control over the energy and the current density of the bombarding ions.

≻ Ion Beam Sources

Permits Sputtered coatings to be deposited at very low inert working-gas pressure (<10-4Torr)

onto substrates not in contact with a plasma.

≻ Good Film Thickness Uniformity

Even with targets of same diameter as substrate.

≻ Low Pressure Process

Maintains discharge at a pressure range of about 10-4Torr (roughly one order of magnitude

lower than the conventional sputter discharge pressure.)

-

Specifications

제품 Specifications

Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Turbo molecular pump

Loadlock Chamber

N/A (Optional item)

Substrate Heating Unit

SiC / 4”, 6”, 8”

Sample Loading/Unloading Unit

N/A (Optional item w / Loadlock chamber)

Pressure Control Unit

Auto / Semi-auto

Vacuum Gauge Controller

Vacuum Gauge Controller

Gas Supply Unit

Gas Supply Unit

Power Supply Unit

RF

Target Size

2”, 3”, 4”, 6”

Film Thickness Uniformity

Less than ±5%

Ultimate Pressure

Less than 5.0E-7Torr

CE Certification Acquired Specifications

ITEM

SPECIFICATIONS

Process Chamber

Stainless steel

Vacuum Pumping Station

Turbo molecular pump

Loadlock Chamber

N/A (Optional item)

Substrate Heating Unit

SiC / 4”, 6”, 8”

Sample Loading/Unloading Unit

N/A (Optional item w / Loadlock chamber)

Pressure Control Unit

Auto / Semi-auto

Vacuum Gauge Controller

Vacuum Gauge Controller

Gas Supply Unit

Gas Supply Unit

Power Supply Unit

RF

Target Size

2”, 3”, 4”, 6”

Film Thickness Uniformity

Less than ±5%

Ultimate Pressure

Less than 5.0E-7Torr

CE Certification Acquired -

Options

-

Control

제품 Control

System Control

Vacuum

This screen shows the pumping screen. This screen consists of

each valve, pump action button, automatic button. The biggest

difference from Semi Auto is the automatic button, so if you

proceed with these buttons in sequence, one sample will be

completed.

Process

The figure shows the process screen. This screen shows the

buttons that can control the gas flow rate, valve, power etc.

required for the process.

Recipe

The figure shows the recipe screen. This screen contains boxes

for entering the process conditions required for deposition. Input

all the boxes and press the Process button to automatically

deposit according to the input process conditions.

Transfer

The figure shows the Transfer screen. In this screen, there

are buttons that allow you to manipulate the part you will use

to move samples from the load lock chamber to the process

chamber, such as the loading arm, z-motion.

Graph

The figure shows the graph screen. This screen shows vacuum

degree, power amount, deposition rate, thickness and so on.

You can record that data and make it into a file and compare it

with the previous data.

Message

The picture is a graph screen. The picture consists of status

message notification messages

System Control

Vacuum

This screen shows the pumping screen. This screen consists of

each valve, pump action button, automatic button. The biggest

difference from Semi Auto is the automatic button, so if you

proceed with these buttons in sequence, one sample will be

completed.

Process

The figure shows the process screen. This screen shows the

buttons that can control the gas flow rate, valve, power etc.

required for the process.

Recipe

The figure shows the recipe screen. This screen contains boxes

for entering the process conditions required for deposition. Input

all the boxes and press the Process button to automatically

deposit according to the input process conditions.

Transfer

The figure shows the Transfer screen. In this screen, there

are buttons that allow you to manipulate the part you will use

to move samples from the load lock chamber to the process

chamber, such as the loading arm, z-motion.

Graph

The figure shows the graph screen. This screen shows vacuum

degree, power amount, deposition rate, thickness and so on.

You can record that data and make it into a file and compare it

with the previous data.

Message

The picture is a graph screen. The picture consists of status

message notification messages

-

사용후기

-

상품문의

-

배송/교환정보

[배송]

배송 안내 입력전입니다.[교환]

교환/반품 안내 입력전입니다.

선택된 옵션

-

KVIS-4000L+0원